Jerry Tyrrell shares a couple of contrasting case studies that highlight the good, bad and the ugly when it comes to building products and customer service in this country.

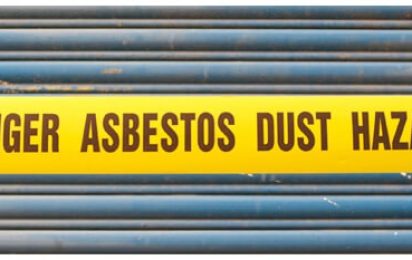

I’m hard (but fair) on manufacturers who give us products that are not fit for purpose or have installation rules that contractors are unaware of. And with so much product coming in direct from Asia that isn’t engineered to our local needs, it’s only going to get worse.

Imagine if government and industry actually created a central register of building failures, so most of us did not repeat the costly mistakes unnecessarily. Products such as acrylic membranes, untreated Oregon deck joist, wet area particle board, slippery floors, lime wash coatings, salt staining from tile beds etc. could all be placed on there. Then again, how many builders and tradespeople would take the time to consult such an information asset?

There are so many products that either need remedial work or look horrible and affect our reputation. Besides, it is so much cheaper over the life of a building if unnecessary maintenance and replacement is avoided. The cheap yellow zinc coating on dyna-bolt type fixings and screws rust quickly and is costing Australia 20 times the small added cost of galvanised or stainless fixings. FC sheet jointing is still cracking. Thin PVC stormwater pipe is easily punctured and flops around with ground movement. Merbau is rotting at the fixings. Plasterboard in basements, garages and wet areas is too easily water-damaged. And why do the codes allow us to install fibreglass or cellulose installation in an area subject to damp?

You’d think manufacturers would love helping contractors and designers with any problem related to their products because they could use the technical feedback in R&D to change formulations, details and coatings in future production runs. But I do not see them using the same approach of the medical profession or aircraft industry where there is an attitude of ANDSNTTBB (Always Never Don’t Not Stop Trying To Be Better). Thanks Bill Gauley for that wise acronym.

I recently installed a few 6m x 3m decks, using a locally manufactured wood/composite product for the first time. However, after my experience, I will not use or specify this product or similar ones again. In my opinion it scuffs and stains.

Movement is different to timber – it will grow in length as well as width. But there were some other substantial issues too:

Noise is a problem because the edges have a recess; each joint is potentially a woodwind instrument.

I suggest contractors are unfamiliar with their technical installation method .

Protracted and unhelpful technical support process. They proposed slipping strips of gutter-guard or O rings in every joint. Imagine what your clients would say about this on their new deck…

The possible breakdown of relationships with suppliers. My contract was with the timber supplier – old friends I have been buying from for decades. I spent at least $1800 trying to stop the noise before I realised the manufacturer already knew about the problems. So I withheld this from the timber supplier which wasn’t nice, but the only way to get cost recovery without legal action – and maybe I had done everyone a favour.

The product manufacturer tried all the usual excuses: not complying with their installation instructions (which were never provided to us), inviting us to provide an analysis of the installation (which was their job). Eventually the supplier did take the time to fly up from Melbourne when he realised I had some genuine concerns.

I sincerely hope all suppliers of similar composite decking products take this feedback and improve their products, so they can be installed without significant departure from known trade practice and perform as advertised. I also hope their product is supported by effective after sales service. What they might be able to get away with in marketing to the DIY enthusiast is a lot different to dealing with seasoned builders.

By the way, I did pay my timber supplier in the end after we negotiated a $1650 discount on a large order of joinery timber.

Getting suppliers to own up to their mistakes

As your favourite Jerry Builder, I sourced 67 louvre windows from a Chinese manufacturer who is an Australian Window Association (AWA) member with appropriate product certification. One of the reasons for my decision was based on the fact they used a top brand name hardware I was familiar with for the louvre galleries as I find most Chinese galleries can be flimsy and break. I spent at least 12 months detailing everything and questioning them to get everything right… or so I thought. I was very careful to ensure the windows were sized for a full glass blade.

When the shipment arrived onsite there were no galleries. The louvre supplier suggested the hardware supplier would be supplying its items separately, only for me to be told the following from said supplier: ‘As it stands we are unable to supply this product for technical issues beyond our control’.

Wow, so for once all the naysayers cannot blame China. I nudged the hardware supplier for assistance but I ended up paying for installing the galleries when they eventually arrived and supplying and fitting a 30mm strip of unnecessary glass.

Unaffected by their atrocious service, the hardware supplier even declined to source the strip glass to assist, even though I was willing to pay for the glass just to get the problems sorted. Customer service… what customer service? They’ve lost me.

Back to publication

Back to publication