Jerry Tyrell continues his RULES project by focussing on windows and doors.

Windows and doors

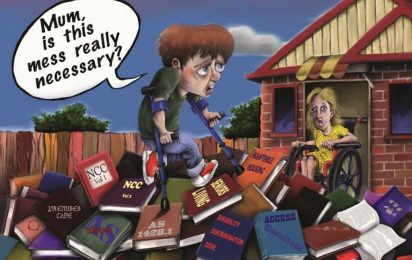

The National Construction Code (NCC) tells us we must construct a building ‘to provide resistance to moisture from the outside that could cause unhealthy or dangerous conditions, loss of amenity for occupants or undue dampness or deterioration of building elements.’ It directs us to Australian Standard 2047 without actually explaining how this document can best be used.

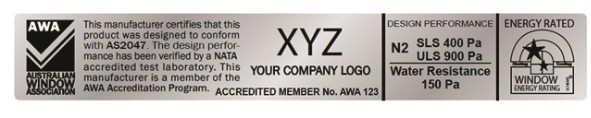

The 1999 version of AS 2047 was called Windows in buildings. The update of AS 2047 in 2014 has the more appropriate title Windows and external glazed doors in buildings. Besides the more complete name, this document is better structured and set out than most Standards. By that I mean it guides us to ensure all windows and doors we design, purchase and install are fit for purpose. At last, the rules being set protect our clients by making sure the supplier gets the base product right. That assumes the supplier you chose is reputable and not illegally bringing non-compliant product out the back door from China or elsewhere.

I do not intend to tell you how to carry out the elaborate testing required in AS 2047 and the other Standards it refers to. I have not dealt with glass quality, seals, putties, gaskets, mohair seals or visual indicators. You do not need to know how the cyclone resistance or coating quality of any window is tested or verified. What you do need to know is how you:

– verify the supplier has tested and certified their products under strict guidelines

– look for suppliers who are members of the Australian Window Association and who stick by the requirements of that organisation

– must install all products carefully using the principles of good building that my RULES Project is all about.

Definitions

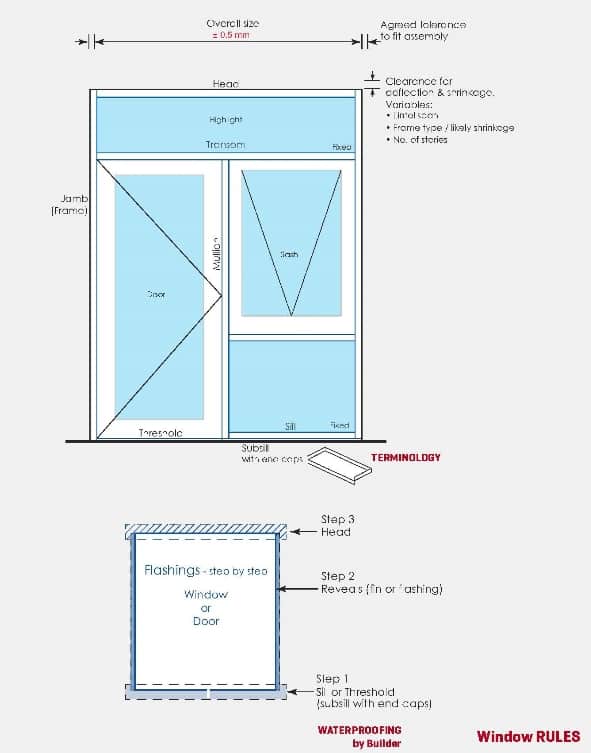

As usual with Standards, different terms are used for similar things e.g. durability, resistance to weathering, atmospheric environment. And definitions are missing e.g. window pressure rating, window exposure classification. I’ve included a diagram to explain most terms.

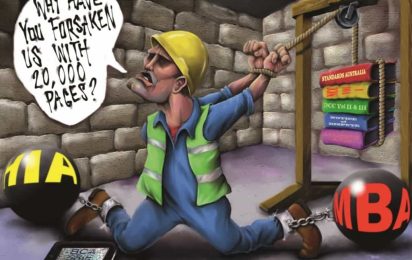

THE SOURCE DOCUMENTS

NCC (National Construction Code) Volume 1: approx 3 pages

NCC (National Construction Code) Volume 2: 10 pages

AS 2047 – 2014 Windows and external glazed doors in buildings: 66 pages

AS 1288 – 2006 Glass in Buildings – Selection and Installation: 134 pages

Other referenced Standards in AS 2047: Over 1000 pages

Australian Window Association Guide to Window & Door Selection https://www.awa.org.au/resources/a-guide-to-window-and-door-selection

Fit for purpose

Fit for purpose may seem a bit vague. In essence, it means any product you use should be good enough to last the economic life of the building. The Australian Building Code Board (ABCB) in its Durability Code says this is a minimum 50 years! And even though we builders tend to think only in terms of 6-year home warranty, any unnecessary failure or replacement during the life of a product discredits our industry and bequeaths future owners (and therefore Australia) with excessive maintenance costs, wasted carbon and lost productivity. And of course any 6-year warranty a supplier may offer will be void if you haven’t correctly installed and maintained the windows to the manufacturer’s requirements.

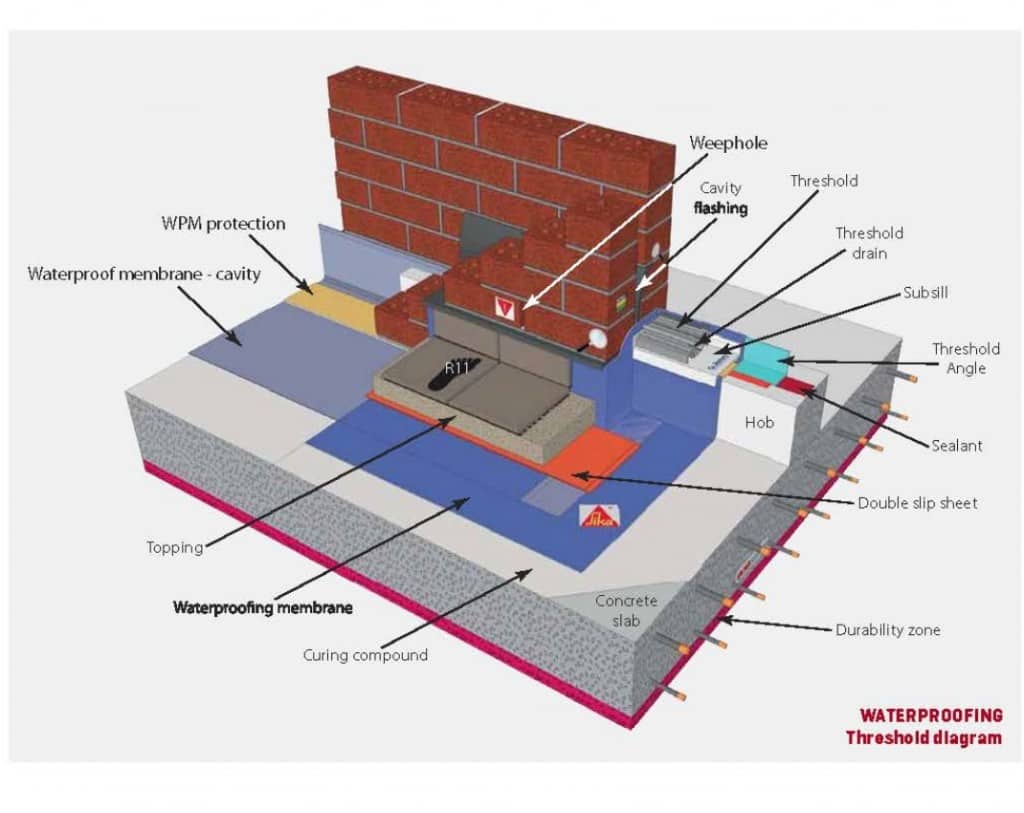

This deals with the product your clients want – the actual window or door. But you will need to install it properly. This is also a fit for purpose moment. And I remind everyone that the number one post-completion cost to our industry is fixing up leaking thresholds and sills. Fortunately most of you have good common sense. And many of you have been taught by skilled tradesmen and craftsmen who use time tested ways to flash their windows and doors. Just understand that the NCC is not a document that will direct you towards the ‘precise’ (summary) techniques necessary to prevent mistakes and problems when we install windows and doors.

From my experience, the issues builders and tradesmen often overlook, even if they are well trained are:

– drainage from thresholds and sills

– window installer and waterproofer not working together

– future trades unintentionally covering weepholes and drainage slots

– remedial work that seals in problems and makes the leak worse

– pressure differences between inside and out where there are no overhangs or protection from extreme weather conditions

WARNINGS

There are so many products and techniques we should never use, even when they are supposedly allowed.

Follow suggestions below and I can assure you your reputation will be enhanced for decades to come.

– level the sill/threshold first and pack with fibre cement or similar material every 300mm

– never secure long threshold through the threshold – back fix them to an angle and seal rivets

– plumb and pack between side frames and wall frame then always check square (diagonals should be equal)

– ensure you fill gaps between wall and frame with foam or insulation

– do not use galvanised concealed fixings – use stainless steel. Fix to manufacturer’s requirements and provide additional fixing at striker

– never use untreated/non-durable timbers in a window – and prime ALL cut ends/joints of durable timbers

– top fix frame heads wider than 1.2m. Check this prior to handover so you can correct any movement / shrinkage out of level especially top hung multi-fold doors

– use twin or four roller units under heavy sliding doors

– securely fix the fixed door in stacker doors so they do not get displaced

– extend head and sill flashings a minimum 150mm both sides of opening

– always turn up sides of your sill and threshold flashings

WEATHERPROOFING

– always, always, always use a subsill under weather exposed thresholds and use properly sealed endcaps even if you have to make these yourself. Refer to the 3D Threshold diagram

– seal tops of fins against water entry or fit reveal flashing

– fit head flashing OVER reveal flashings. Fit Sisalation over the head flashing

– do not use MDF for reveals.

– outward opening hinged doors are less likely to leak

– most double hung and sliding windows allow a lot of water to blow in if you leave them open when out. Louvre windows allow ventilation and minimum water entry. They are reasonably secure and don’t allow children to fall out of them

– multi-fold doors are best top hung and clients should be warned that joints in these doors will leak in extreme weather. DO NOT use parquet or timber floors where these doors are installed.

THE PROCESS

1. Design the window or door to suit the needs of the occupant This means you need to get the following things

right:

– wind load – this is the likely load the item will face in the region / height where installed

– thermal performance – different windows and glass are more energy efficient. You will need to know how the window conducts heat (U value) and how much sunlight it gets (Solar Heat Gain Coefficient)

– acoustic – how much noise, if any, do we need to keep out. Rule of thumb, the thicker the glass the quieter it is. But you will need to check how tight fitting / well sealed the sashes / doors are. And stop the noise through gaps around the actual frame itself.

– glare – do you need to reduce glare with tints and reflective films.

– Your Australian Window Association member supplier should be able to provide good advice on most of the above issues.

2. Identify the risk factors

– location height above surrounding buildings atmospheric classification (corrosivity of exterior environment) plus UV

– wind pressure

-sill height above floor/ground level below.

– threshold height above finished floor – can create a high trip risk and dampness problems if the architect wants a level floor between inside and outside

– security – security screens are a good investment for most ground floor windows impact – insect / pet / children – how robust will the screens needs to be

– durability including all seals, gaskets, coatings.

– access for maintenance – all glass and frames will need cleaning and seals checked periodically

– bushfire – requirements for glass and screen mesh will change as bushfire attack level (BAL) increases.

3. Select the appropriate manufacturer

I recommend that you use tried and tested suppliers who meet the membership guidelines of the Australian Window Association (AWA). They verify that tests required by AS 2047 are completed for the window or door including:

– structural – deflection under load

– ultimate strength – the item will not collapse under load set out in the Ultimate Limit State Test criteria

– water infiltration – penetration of uncontrolled water is measured

– air infiltration – any air leakage is identified and measured

– operating force – force needed to open a sash or door is within set limits

AWA members’ products are subject to annual audits as part of their third party accreditation scheme.

4. Install in accordance with manufacturer’s requirements AND best practice

Let me refer you again back to the Warnings section of this article – each job you do needs to be checked against those timely reminders. Don’t assume your staff will always follow those golden rules – supervise, supervise and supervise – after all, it’s your business reputation at risk!

And one last warning – please think through how any water draining into cavities/around your windows will get out.

5. Ensure items are correctly labelled

The AWA example below is concise and industry best practice in my opinion.

6. Obtain Compliance Certificate from manufacturer including review of Test Reports if there is any doubt about validity of the certification.

7. Obtain Certification from your water-proofer for the membrane under thresholds

8. Service/adjust/clean your windows and doors prior to handover, especially any complex door or window. This is one of the first things a client will pick up on if a window or door is difficult to open/close.

9. Give your client IN WRITING the manufacturer’s requirements for maintenance and cleaning.

Back to publication

Back to publication